Slider Section

Who To Work

Simple Working Process

Keeping the outdoor unit clean, and sealing any leaks in your home can improve efficiency

Cool Wave System

Upgrade to the latest energy-efficient air conditioning Frost technology with Eco Cool

Read More →Arctic Installations

The Arctic Blast Repair service addresses all your air Eco Cool conditioning repair needs

Read More →Air Flow Solutions

Our Quick Cool installation and service provides fast and cooling efficient installation

Read More →Emergency Service

We handle everything from assessing your cooling needs to positioning Arctic Blast

Read More →our work

Phoenix Citadel Mall

Entire Mall project, 6000 sqft

C21 Mall

Entire Mall project, 3000 sqft

Pakiza Life Style

Complete project, 5 Major Villas, 5000 sqft

Malhar Mega Mall

Entire Mall project, 2000 sqft

Wall Mounted Air Cooler

Industrial air cooler installed on a factory wall.

Industrial Cooler Outdoor

Outdoor cooler unit mounted on a building.

Stacked Air Cooler

Multiple air coolers stored in a warehouse.

Factory Wall Mounted ooler

Air cooling system installed on a factory exterior.

AC Technician Repairing.

Technician repairing an outdoor AC unit

Indoor AC Mounted

Wall-mounted indoor air conditioner in a room.

Hvac Technician Installing

HVAC technician installing an outdoor AC unit

Apartment AC Outdoor

Outdoor AC unit installed in a residential building.

Luxury False Ceiling

Modern false ceiling with LED lighting.

Decorative False Ceiling

Stylish false ceiling with unique lighting patterns.

Gypsum Ceiling Installation

Gypsum false ceiling under construction.

Modern False Ceiling

Interior designer working on a false ceiling with LED lights.

Assessment & Planning

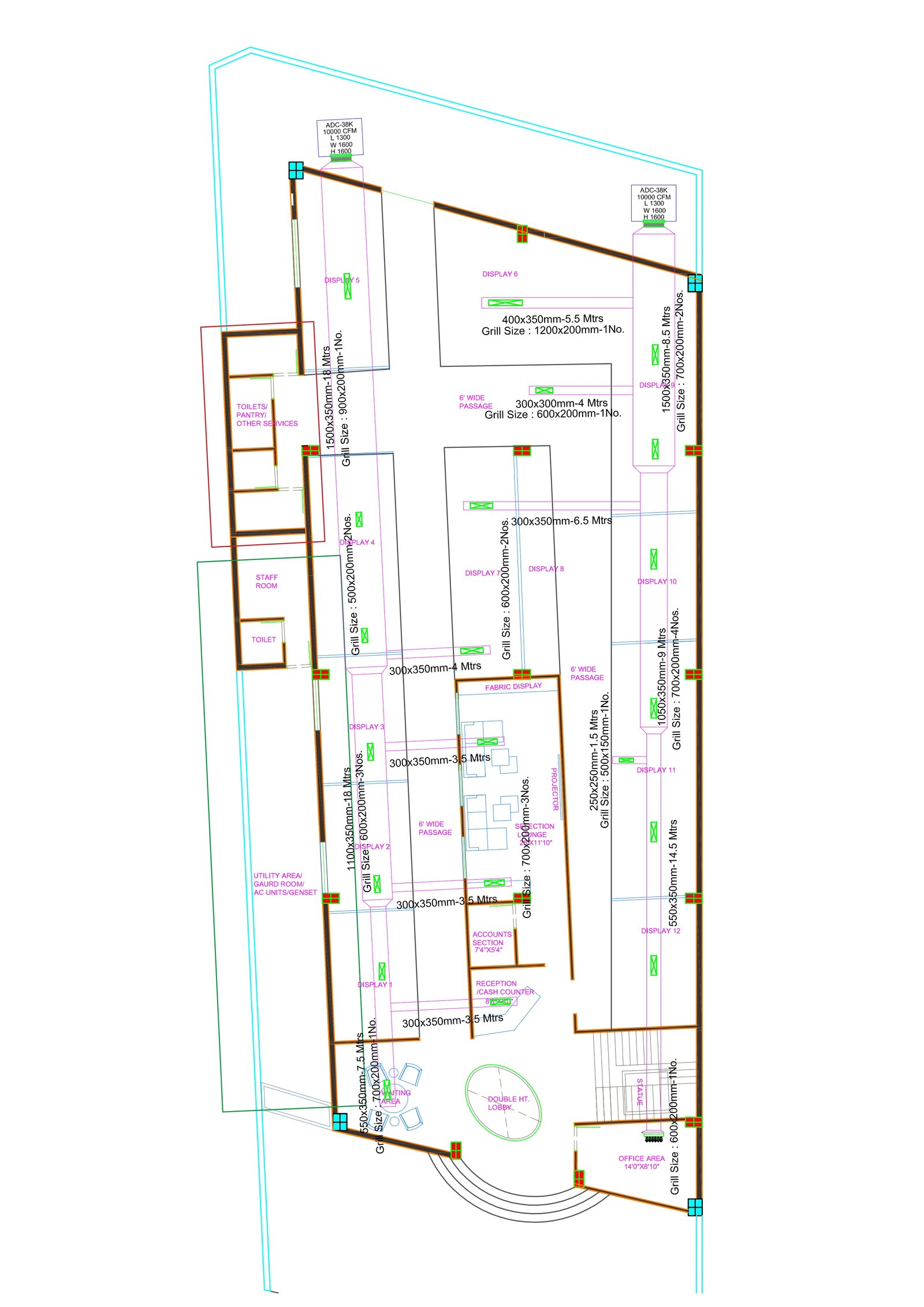

- Analyze building layout: consider room size, ceiling height, and insulation.

- Identify high cooling need areas: large windows, poor insulation, or high occupancy.

- Perform Manual J Load Calculation for precise cooling load (BTUs).

- Calculate required airflow (CFM) per room based on size, orientation, and heat factors.

- Implement proper zoning for independent temperature control in larger spaces.

- Design duct layout: centralize the main trunk, keep branches short/direct, and position vents strategically.

- Focus on balanced air distribution and energy efficiency for consistent comfort.

Architecture

- Duct Placement: Position ducts in accessible areas to minimize resistance and ensure efficient airflow.

- Integration with Design: Incorporate ducts into the building’s layout without disrupting the aesthetic or functionality.

- Zoning: Divide the building into cooling zones for better temperature control and energy efficiency.

- Insulation: Use proper insulation for ducts, especially in unconditioned spaces, to reduce energy loss.

- Noise Control: Implement noise-reducing materials and design to prevent sound transmission through ducts.

- Space Optimization: Ensure ducts do not interfere with other systems like plumbing or wiring and maximize space efficiency.

- Sustainability: Use energy-efficient materials and incorporate passive cooling techniques for reduced environmental impact.

- Maintenance: Design for easy access to ducts to facilitate regular maintenance and inspections.

Duct Design

- Position the main trunk centrally to reduce duct lengths and pressure drops.

- Plan branch ducts for even air distribution based on room-specific cooling needs.

- Size ducts accurately using tools like duct calculators or the "equal friction" method.

- Incorporate zoning systems for areas requiring different temperature controls.

- Minimize sharp bends, long runs, and unnecessary connections to reduce resistance.

- Ensure a balanced design for uniform cooling, energy efficiency, and system reliability.

Material Selection

- Galvanized Steel: Durable, long-lasting, ideal for most systems.

- Flexible Ducting: Easy to install in tight spaces but less durable.

- Fiberglass Ducting: Effective for noise reduction and insulation.

- Use insulated ducts to minimize energy loss, especially in unconditioned spaces (e.g., attics, basements).

- Choose high-quality sealants (mastic, foil tape) for airtight connections and leak prevention.

- Opt for sturdy fasteners, clamps, and sealants to ensure secure and efficient installation.

- Prioritize materials that enhance durability, energy efficiency, and system performance.

Installation Process

- Review the duct layout plan: Ensure all materials and tools are prepared for installation.

- Clear the installation area: Remove any obstructions to allow easy access and proper installation.

- Position the main trunk line: Secure it centrally to optimize airflow and minimize duct lengths.

- Align and support the trunk: Prevent sagging and ensure proper alignment during installation.

- Connect branch ducts to the trunk: Attach ducts securely at designated connection points.

- Route branch ducts to rooms: Minimize bends and keep duct lengths as short as possible.

- Seal duct joints: Use mastic or foil tape to ensure airtight connections and prevent leaks.

- Test the airflow: Check each room for consistent airflow and identify any potential issues.

- Make necessary adjustments: Optimize airflow and system efficiency by addressing detected issues.

- Perform a final inspection: Verify all components are properly installed and functioning as intended.